Gas forehearth

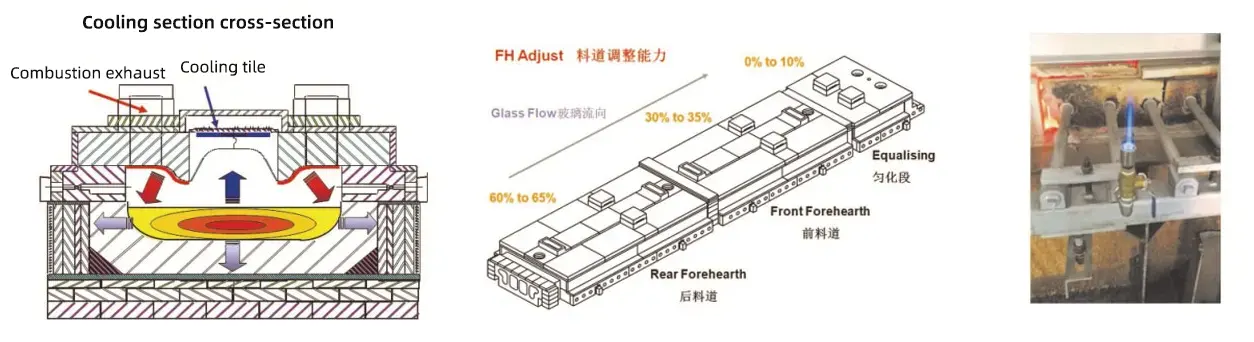

Ruiteng company provides customers with professional design of feeding channel, adopting advanced technology from abroad, the feeding channel adopts manual indirect cooling, high precision of temperature control, higher homogeneity of glass liquid, wider range of pulling volume, the whole process design carries out heat calculation to ensure that all the temperatures are controlled within the design range.

Classification:

Gas Feed Channel

Key words:

Gas forehearth

Graphic Details

Ruiteng company provides customers with professional design of feeding channel, adopting advanced technology from abroad, the feeding channel adopts manual indirect cooling, high precision of temperature control, higher homogeneity of glass liquid, wider range of pulling volume, the whole process design carries out heat calculation to ensure that all the temperatures are controlled within the design range.

The control system includes temperature control of distribution channel and supply channel, frequency converter and display, etc. The system automatically records the temperature profile and other operating parameters and stores them in long-term records.

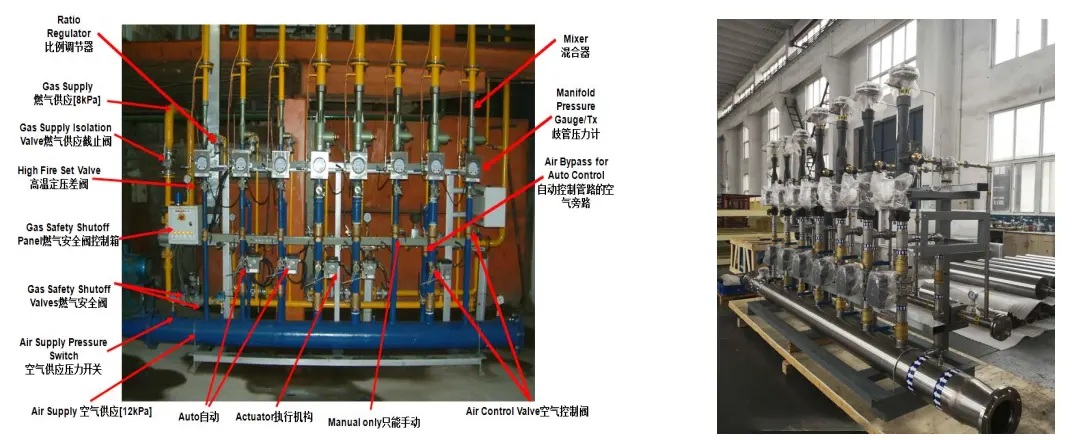

The combustion system utilizes a pressure pulse-loaded proportional regulator, mixer and proportional motor-controlled combustion air to ensure a constant ratio of air to natural gas within the normal operating range. The burner can be operated in the range of 2 mbar to 40 mbar in the burner line.

It covers many industries such as bottles, jars, utensils, insulators, glass bottles, glass tubes, microcrystalline glass, glass wool, glass fiber and so on.

The system consists of 5 pre-assembled frames and line pressure gauges and transmitters. The frames are equipped with pressure switches to detect low pressure air and gas mixtures. These pressure switches are connected in series to natural gas safety shut-off valves. Detection of a pressure switch deviation reaching an alarm condition automatically shuts off the gas supply and an audible and visual alarm alerts the operator. Each frame requires front and rear access and is on an in-line machine platform.

German imported control actuator

Safety designed German double solenoid valves (fast and slow shut-off open) to ensure the safety of the gas system.

Manifold pressure display is provided in each zone. For safe adjustment of nozzle pressure to ensure safe operation of combustion system.

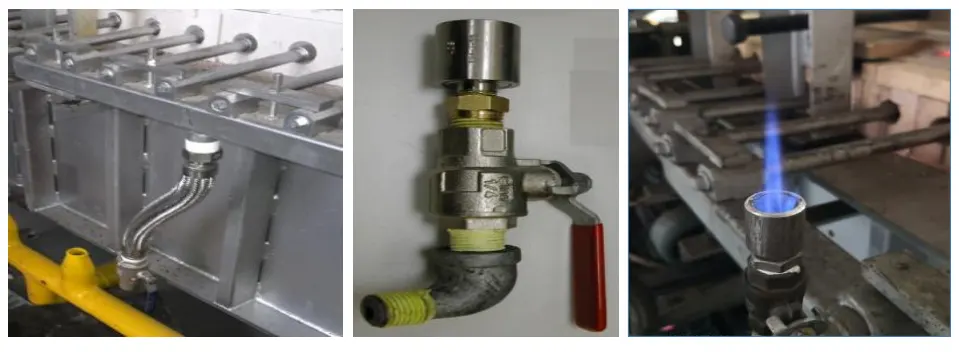

Spray gun type: gas / air mixing spray gun, spray gun tail with maintenance holes, soft connection with manual valve, easy to maintain.

Each nozzle is equipped with a flame ratio checking nozzle (flame ratio can be checked at any time).

Adopt Wenli or orifice plate flow mixer design, nozzle small flame to large flame combustion ratio is constant, is the basis of energy saving and high efficiency of the gas material channel; manifold pressure is set between 2-25 mbar to maintain the stability of the glass liquid, reduce the scrap rate, droplet stability, such as pressure blowing process of choice.