Row and column bottle making machine

Row-type bottle-making machine is used to produce a variety of glass containers automatic bottle-making machine, the number of products produced accounted for more than 80% of all glass bottles and jars. Row machine according to its molding process is generally divided into blowing - blowing method (manufacturing small-mouth bottles) and pressure - blowing method of 2 types of process types.

Classification:

Determinant Bottle Making Machine

Key words:

Row and column bottle making machine

Graphic Details

Row-type bottle-making machine is used to produce a variety of glass containers automatic bottle-making machine, the number of products produced accounted for more than 80% of all glass bottles and jars. Row machine according to its molding process is generally divided into blowing - blowing method (manufacturing small-mouth bottles) and pressure - blowing method of 2 types of process types.

Blowing - blowing method is mostly used in the manufacture of small-diameter glass bottles and jars, the process is: loading T puffing - inverted blowing (initial type of blowing) T prototype flip - positive blowing and curing bottles and jars cooled T clamp bottles T cooling conveyor.

Pressure - blowing method is mostly used in the manufacture of large-diameter glass bottles and jars, the process is: loading - stamping to take the shape of the prototype - prototype blowing T prototype (initial) bottle turnover - positive blowing and curing and cooling - clamp bottles T cooling and transportation.

Strictly control and select the materials of key components, heat treatment and manufacturing precision to improve the service life.

Selection of world famous brand bearings, valves, seals, to improve the life and reliability.

Sealed oil lubrication ensures reliable lubrication of hinge oil tank and cam oil tank.

Automatic lubrication system

Precision gear-driven bottle clamping cantilever mechanism and quick-change bottle clamping fixture.

PLC controller electrical control system

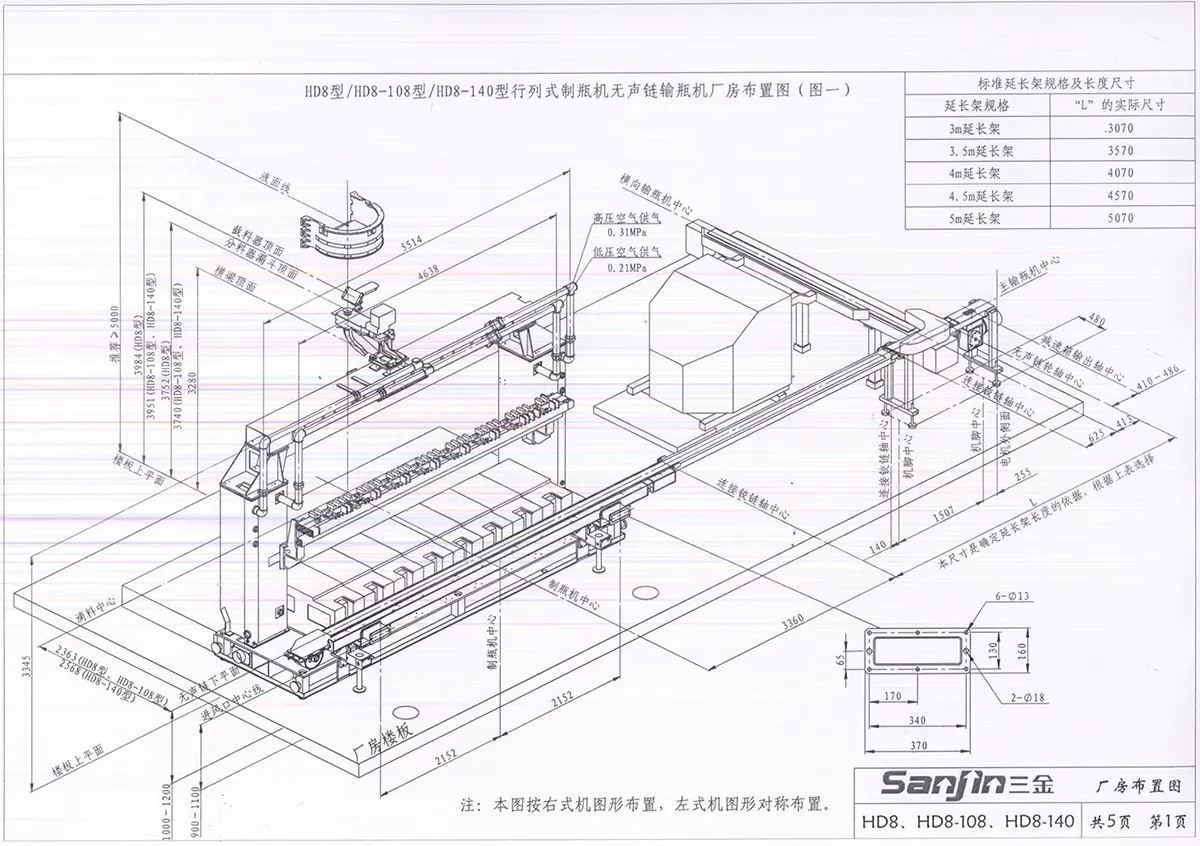

Installation Diagram

HS type 85×2 three-drop bottle making machine

♦ Servo Dispenser

♦ Servo Clamp Shifter

♦ Servo Tumbler

♦ Electronic bottle toggle (double motor or single motor bottle toggle)

♦ Split Hanging Material Flow System

♦ Quick Change Pressure Blow Mechanism with Guided Positioning Plate

♦ Quick-change check valves for funnel, puffing, positive blowing and switching mechanism.

♦ Precision adjustable vertical clamp jaws.

♦ Quick-change arm with graduated scale

♦ Puffing, funneling, positive blowing mechanism with centering ring and closing cam.

Vertical cooling and vacuum forming mold base mechanism.

♦ Flexible line synchronization system with multi-division auto-phase adjustment.

♦ Equipped with small port pressure blowing function

● 26-way pneumatic valve box (21-way pneumatic valve box optional)

● Primary mold clamping mechanism

● Primary mold nozzle cooling

● Air puffing mechanism

● Funnel mechanism

● Hydraulic cushion tilting mechanism

● Mouth clamp fixture mechanism

● Mold clamping mechanism

● Servo clamp mechanism

● Mold nozzle cooling

● Mold base unit, frame air inlet

Flow system

● Synchronous belt servo divider

● Fixed-angle dual-axis cut-offs

● Split flow system

● Flow system options

● Tie-bar servo dividers

Main frame

● The main frame consists of a welded chassis, columns, beams, distribution box, preliminary side distribution box, and piping.

● The distribution box and piping are made of corrosion- and rust-resistant materials.